Pharma Equipments

biggest manufacturer of pharmaceutical equipments and biotech lab furniture at reasonable price available in market - Offering Chemical Storage Tank, Powder Container, Clean room Furniture, Change Room Accessories and Machinery

Pharmaceutical Machinery

Pharmaceutical Powder Container

Change Room Accessories

Clean Room Equipment

We are also counted among as the real manufacturer Pharma Equipments, Pharma machinery and SS Furniture.

Clean Room Furniture

We are the leading one in this field as a large manufacturer, supplier and exporter as a wide assortment. Our leading position is possible due to our great work, superior quality of product, fine design and the market demanded furniture’s from our company.

specially manufactured with the advanced quality of the materials and also having the modern forms of the production line and machineries to produce the well equipped forms of clean room furniture’s for the major requirements of the varied places.

SS Pharma Equipment

This wide range of products we deliver is a result of the extremely talented workforce that handles each and every process held in the industry. The experts in our industry check each model under the standard specification and verify their efficiency of performance under number of quality check parameters

The range of SS pharma equipment we offer are famous for their unparalleled features like smooth finishes, capacity, size, corrosion resistance, low maintenance, etc. Various industries demand our pharma products for their supreme performance, quality and durability.

Washing of vials, Ampoules and bottles is the significant process in the pharmaceutical industries that cannot be taken as granted as it determines the hygiene and the quality of the products filled in them. A meticulous and thorough washing in a very clean, hygienic and uncontaminated manner is the basic requirement of this step

TOTAL VIAL WASHING MACHINE

AUTOMATIC BOTTLE WASHING MACHINE

MULTI JET VIAL WASHING MACHINE

BOTTLE WASHING MACHINE

SYRINGE SEALING MACHINES

AMPOULE WASHING MACHINE

Pharma Bottle Washing Machine

Our Total Vial Washing Machine adheres to international pharmaceutical engineering standards. We supply these machineries according to the specific requirement of the clients.. Our assortment of products are marketed in the export market of USA, Belgium, Greece, Norway, Spain, Zimbabwe, South Africa, Nigeria, Ghana, United Kingdom, Brazil, Colombia, Venezuela, Iraq, Kuwait, Jordan, Cuba, etc

-

Vial Washing Machine Price

-

Automatic Linear Vial Washer

-

Total Vial Washer

-

Automatic Linear Vial Plant

-

Tunnel Type Vial Washing Machine

-

Pharma Vial Washing Machine

-

Vial Washing Machine Manufacturer

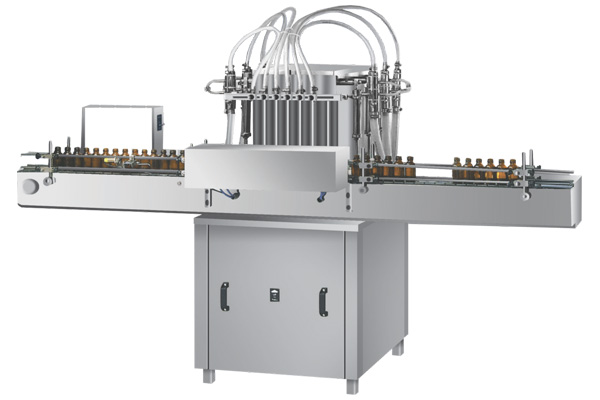

Liquid Filling Machine

We are most reputed and leading Liquid Filling Machine Manufacturer and supplier in all over the India. Liquid filling machinery is the domain of our expertise. Proficient combination of engineering expertise and merchandise experience is ideally resulted in to greater quality series of liquid filling machines. Our inventory includes Vial filling machine, vial bottle filling machine, bottle filling machine and automatic liquid filling machine.

Vial Filling Machine

Vial Bottle Filling Line

Bottle Filling Machine

Automatic Liquid Filling Machine

Liquid filling machines come in various structures relying upon level of their programmed working, the containers wherein the liquid is to be filled and number of heads the machine needs to empower the particular number of bottles or container filling at once

FOOD COLORS

We are prime manufacturer of Food Colours, since the establishment of the company in 1988 based in Ahmedabad, India. Our wide range is equipped using food grade raw material and is reckoned across the world for its quality and purity

-

SYNTHETIC FOOD COLOURS

-

BLENDED FOOD COLOURS

-

INDIGO CARMINE FOOD COLOUR

-

AMARANTH FOOD COLOUR

Synthetic food colors are also known as artificial food colours, are manufactured chemically and are the most commonly used dyes in the food, pharmaceutical and cosmetic industries, soft drinks, beverages, desserts, confectioneries, jams and jellies, decoration and coating, pickles, sauces and seasonings, meat and fish products and many more

Acid Dyes Manufacturer

Our acid dyes have use in nylon, silk, wool and improved any of numerous synthetic fibers polymerized from acrylonitrile from neutral to acid dyes manufacturer baths. Manufactured keeping the various requirements of our clients in mind, our acid dyes are non-caustic, are in many cases non-toxic and deliver superior results.

-

Acid Black Dyes

-

Acid Brown Dyes

-

Acid Brown Dyes

Acid dyes are used for dyeing wool, nylon, certain acrylics such as Tvpes 24 and 28 Orlon, and other chemical fibers

Caramel Colors

Matrix Pharma Chem was established in the year 1988. We are chiefly into manufacturing, supplying and exporting wide-ranging food colorants such as Carmoisine Food Color, Caramel Powder, Natural Liquid Caramel Colors and Chocolate Brown HT Food Color etc. Under the guidance of our expert Mr. Jagdish Patel, the different departments of our company such as research & development, manufacturing, quality control, warehousing & packaging, and sales & marketing etc endeavor for offering excellent quality products to our customers.

Caramel colors are water soluble and is widely used as a food colorant. It also acts as an excellent emulsifier and hence is used for emulsification in food preparations. The color of this substance may vary from very pastel yellow to chocolaty color.

Rotary Tablet Press

Our experts made each pharmaceutical instrument of Irregular Shapes Tablet Punches & Dies, Mini Tablet Press Machine, Tablet Inspection Machine, and Tablet Compression Tooling are made with the highly developed technical methods and advanced machineries by producing our products as the uncontaminated & tough in nature

-

Single Rotary Tablet Press

-

Double Rotary Tablet Press

-

Mini Tablet Press

-

Tablet Inspection Machine

Single Rotary Tablet Press is subsequently valued by our clients as high rising requests among that of our rivals. We offer this to our customers at exceptionally reasonable costs.

TABLETING MACHINES

Jayshree Tablet Science has been providing solutions for tablet making solutions for over 25 years. We are renowned for our premium quality of Pharma machinery. We design the equipments specifically to meet the unique requirements of our clients. We have engraved a position in the industry by manufacturing equipments that are accommodating, dependable and precise.

Our manufactured Tablet Compression Machines are accessible at highly affordable prices and durable too. Besides these we do also provide tablet printing machines to print on tablets and capsules.

pharma lab machinery

Jayshree Tableting punches & Dies was founded in the year 1992 where it’s actively manufacturing tablets tools for the pharmaceutical, Ayurvedic, Candy, Storage Battery and ceramic Industries for the home and global market. Our offered pharma machines and tools are manufactured by our professional using higher quality materials with the help of supreme latest technology in compliance with the industry standards. The products provided by us are highly applauded among our customers owing to their qualitative features such as corrosion resistance, fine finish, high strength, easy installation, precise dimension etc.

With all of the above factors playing a major role in our successful endeavors the other factor that has made a contribution in our huge market. Cost effective products combined with on time delivery is the key of our unmatched success.

Vibro Sifter India

First thing to be known that Vibro sifter is also popularity known as Gyro screen. Vibro sifter which ensures the correct product quality of powders or liquids is achieved by removing oversize contamination. Vibro sifter is designed on the principle of the Gyratory motion and one of the most versatile and universally adaptable machines working across spectrum of industries

Vibro sifter or vibro screen are used by industries like pharmaceutical, Agro , Agro processing, chemical, China clay, food , Dyes, Mines and minerals, powder processing plastic, PVC Petrochemical, paper and many more.

SS storage tank

We are focused on conveying superlative quality as we are sponsored by our profoundly talented man power and works as we fuse best crude material accessible for the last deliverable. Besides, to finish every one of the procedures of our business, we have developed for ourselves a huge and outfitted infrastructural unit which is all around furnished with every one of the instruments, innovation and machinery

We at Jaliyana Equipmentss manufacture SS Storage Tank from 50 litres to 100,000 litres which can be utilized for different applications, with the following accessories and attachments.

PHARMA EQUIPMENTS

Pharma Machines and Equipments are flourishing on well-organized leadership, engineering superiority, cutting technology and proficient approach. Empowered with superior technology an assortment of high quality Pharmaceutical Machineries and Equipments from production to packaging are accessible in the market. The equipments accessible are of all sizes for manufacturing of Tablets, Capsules, Ointments, Cosmetics, Liquid for Pharmaceutical Industry.

We guarantees to supply you the consummately ensured pharma lab equipments with your reasonable value extend as we are looking for the clients compensates in regards to our products.